This does not mean you are stuck. Many knitters, especially when they are just learning to knit, get stuck on the idea that you can only use the yarn that the pattern is written with. There are, occasionally, a few projects where it can be quite hard to find an alternative but that is very rare.

There are a few factors that you want to think about when changing yarn.

Yarn Thickness

The main one is the thickness of the yarn. This is the one factor that you absolutely have to consider. Everything else that I discuss below helps to hone your decision down but yarn thickness is at the core of a project. If you use a thicker yarn, it could make the fabric too dense and often make it impossible to match the gauge of the pattern. If you use a thinner yarn, then it will be more open and airy than intended; there’s more scope with this but some projects such as toys and blankets will not suit an open and airy fabric. Ideally, you want to use the same thickness. You can change it but it helps to know what results you will get from this.

If you come to knitting yarn with no knowledge, then you can see that one yarn is thicker than another but that doesn’t necessarily help you. Luckily, others have done the work for us and the vast majority of yarn companies or local yarn shops will tell you what the thickness of the yarn is.

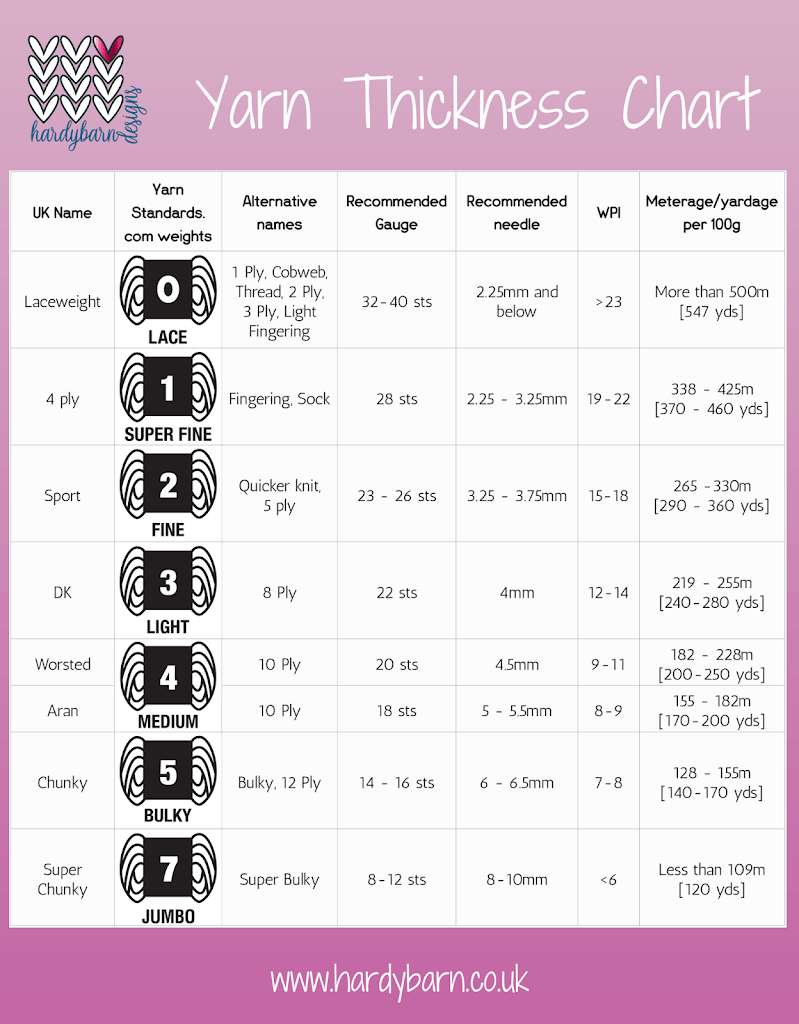

In the UK, we use the following classifications for yarn thickness. Other countries have different names and systems for the thicknesses of yarns, and these alternative names are included in the table.

Should you find a yarn that doesn’t make it clear what weight it is then check the yarn label. Most commercial yarn labels will include –

- composition e.g. 100% wool

- recommended gauge e.g. 22 sts and 28 rows in 10cm [4”]

- recommended needle or hook e.g. 4mm

- total metres/yards e.g. 125m [137yds]

- total weight per ball/hank e.g. 50g

- washing instructions

You can use this information with the table above to work out what the weight of yarn is.

22 stitches gauge, 4mm needle and 250m per 100g indicates that the yarn is a DK weight.

If in doubt, ask your LYS or the yarn manufacturer.

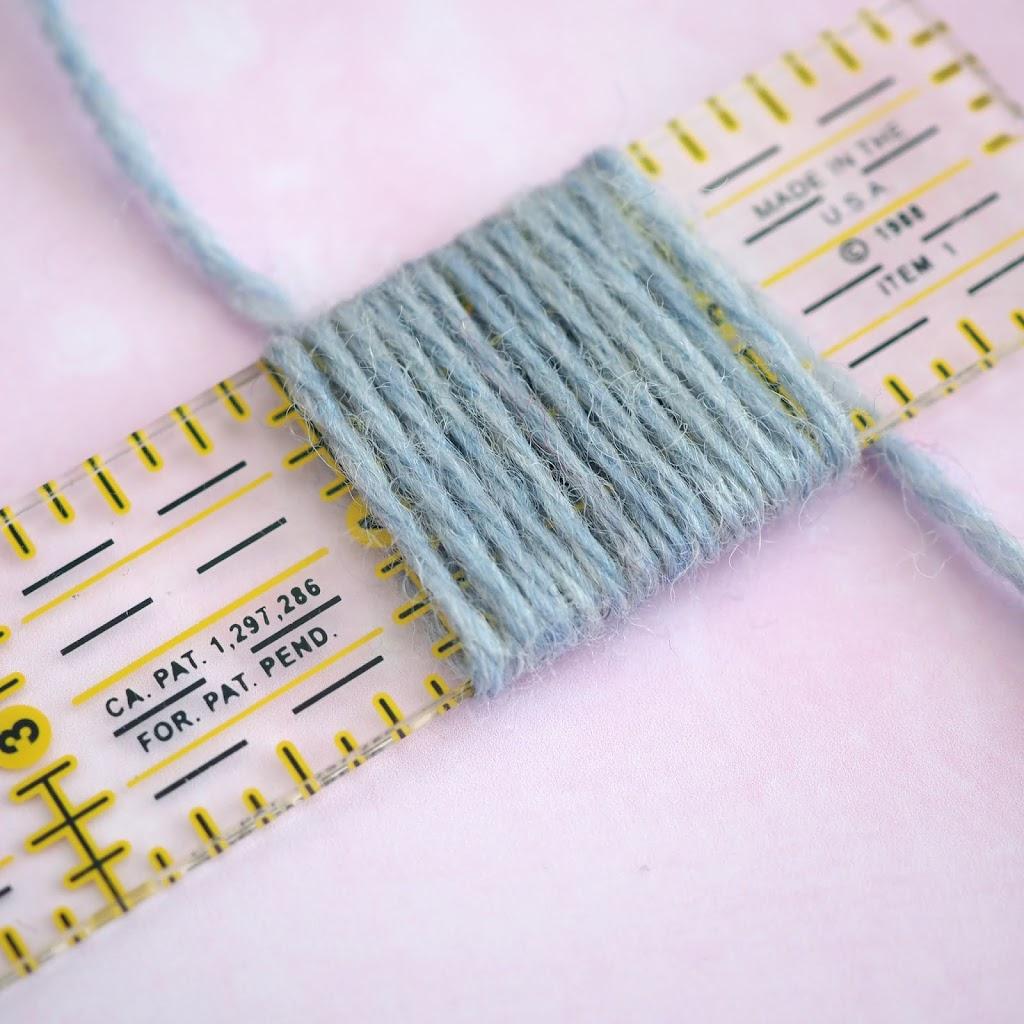

Things become a little trickier if there’s no label. You can use the wrap per inch (WPI) figures in the chart. Wrap some of the yarn around an inch of a ruler. Makes sure there is no gaps between the wraps but don’t compress them together. Count how many wraps there are and see which weight this matches in the chart.

As you can see in the picture, I have 13 wpi, which indicates that it is a DK – which it was.

This gives you a starting point, you can also work out the meterage but this is a bit more complicated. Just be aware that there is no industry standard for WPI and different charts will give you different numbers.

Fibre

We’re going to assume that you’re using the same weight yarn as the pattern. The next factor that you want to consider is the fibre content. Different fibres have different properties and that’s a very long discussion for another day. If you can match the exact composition of the original yarn, then that’s great. In our previous example, we had a 100% wool yarn. If I can find an alternative 100% wool yarn, then I don’t have to consider the effect of the fibre.

Consider what the project is – a garment, shawl, socks, baby clothes?

What’s the most important factor for these projects? Consider these –

- drape

- stitch definition

- feel

- durability

- easy clean

Which do you consider to be the most important for each project? A lot of yarn substitution is personal choice.

Each project would be different, as the stitch pattern will effect the choice. For example, a cardigan.

- If it had a textured stitch pattern, then I would want good stitch definition and a colour that showed it up.

- If it was lacy, then drape would be important.

- If it’s plain and going to be worn a lot, then a long-lasting fibre would be best.

- If it’s for a baby, then being able to machine wash would definitely be a good idea.

If you really don’t know where to start with your choices, then trying to match fibre type would be a good start. There are 3 fibre types – animal, plant and man-made.

For example, if I had a project that called for 100% cotton, which is a plant fibre, then I’d try and match for a yarn composition that had a majority of plant fibre.

| Animal Fibres | Plant Fibres | Man-Made Fibres |

| Wool | Cotton | Nylon |

| Alpaca | Linen | Acrylic |

| Mohair | Hemp | Polyester |

| Cashmere | Nettle | Viscose including bamboo |

| Angora | Rayon | |

| Silk |

Length

The next factor to check is the length. As you can see from the yarn thickness chart above there’s quite a range within each yarn thickness. Compare the length from the original yarn to the one that you’d like to use. If they’re close in number then the match should be good. If they’re quite different, this doesn’t mean you can’t use it but it will change the fabric a little. It might be denser or looser.

In our example, the yarn was 125m [137yds] in 50 g. I’ve found a yarn I like which is 240m [263yds] in 100g.

Just multiply your original length by 2, to see how much is in 100g – 250m [274yds] in 100g.

That’s fairly close. It looks like the yarn I like is just slightly thicker. There are a lot of factors that effect the length e.g. fibre, construction, so this is only really useful for an extra double check.

Construction

Not all yarns are made the same. There are several different types of construction, e.g. worsted, woollen, chain, tube, tape, novelty etc.

Try and use a similar construction to get the same results as the pattern.

Making a decision

- Yarn Thickness

- Fibre

- Length

- Construction

These four factors are the main ones that help to make a decision. Yarn thickness is the most important and the other 3 help to refine your choice. Not everything is relevant to every project and it can seem like a lot to think about.

This is where your local yarn shop comes in. They have experience to advise you on your best choice and it’s something we love to do at A Good Yarn. I know I get a lot of vicarious fun from helping to choose yarn for projects.

How much yarn?

You’ve made your decision. The pattern told me I needed to buy 10 balls for my size, so I just buy 10 balls of my new choice, right? Nope. You could easily buy too much or too little.

The important factor to buying the right amount of yarn is the meterage/yardage needed for the project. Most independent patterns will have this information. The larger pattern houses will tell you how many balls you need, so you just have to find out how much length is in each ball. Occasionally, we get a really old pattern brought in by a customer and it’s not possible to find out length on the ball. You can compare similar patterns or use Stashbot to work out your total meterage.

Going back to our example. The pattern recommends 10 balls that have 125m per ball – the total meterage is 1250m. The substitute yarn has 220m per hank. If you were to buy 10 hanks, then you’d have 2200m, which would be lots more than you need. To work out how many hanks that are needed, divide the total meterage by the length in each ball/hank e.g. 1250/220 = 5.68 hanks. Obviously, you can’t buy part hanks/balls, so round it up, You need to buy 6 hanks of the substitute yarn.

If the yarn was produced in 50 g balls, then it would be 110m per ball. If I only bought 10 balls of this, then there’s a good chance that I would run out of yarn. 1250m/110m = 11.36 balls. I need to buy 12 balls to get the same meterage.

Just remember that the recommended meterage is only accurate if you have matched the gauge of the pattern. If you haven’t taken the time to make a swatch for the gauge, then the meterage you have will not be correct.